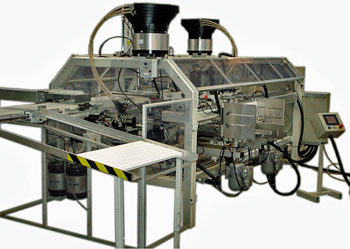

Dan-List Dowel Boring Machine Model BASP 2800

Dan-List BASP 2800 is a semi-automatic dowel boring machine with automatic glue and dowel insert. The machine has a hopper feed and four separate working stations.

It is a compact and solid machine which works standard with eight adjustable boring units and two automatic dowels insert units for insert of dowels in the ends of the work pieces. The boring units are located so the machine drills from ends, top and side, (more can be added upon request).

The Dan-List BASP 2800 has a simple but flexible design, based on a traditional, very strong and solid machine frame, including safety guards and is quite simply built to last.

Dan-List BASP 2800 is a solid, reliable and efficient dowel boring machine, which guarantees a trouble free production run.

The machine is ideal for all components where drillings are required from more than one side and at the same time still needs the automatic insert of dowel in the ends.

Dan-List BASP 2800 has a capacity of up to 800 work pieces per hour.

Equipment:

Standard the Dan-List BASP 2800 is equipped as follows:

- 1 pcs horizontal infeed magazine. Hopper feed,

- 2 pcs boring units for boring from the ends,

- 2 pcs boring units for boring from the top,

- 4 pcs boring units for boring from the sides,

- 2 pcs glue injectors,

- 2 pcs dowel insert units

- 8 pcs pneumatic clamping cylinders,

- Delivery system return to operator, on runners next to the machine.

The boring unit revolve 90° around its own axis, and the boring head itself, revolve 360° around its own axis.

Safety:

As safety for the operator is a keyword on all Dan-List machines, all safety guards which can be opened contain safety switches so if the operator accidently opens a safety guard during production the machine stops.

Or if a safety guard has not been closed properly after set up, the machine will not start.

All safety features are monitored in the PLC control, and can be seen on the touch screen, if any safety devices are activated.

It is impossible for the operator to access the machine in any way during production.

PLC:

The PLC contains many features, for example:

- On/off function for each boring unit,

- Time delay for cross drillings in order to avoid collision for horizontal and vertical drillings,

- Time controlled cleaning function of drilling,

- Programmable counter,

- Adjustable time for air blowing of drilled work pieces,

- Adjustable speed of infeed pusher,

- Adjustable injection time for glue injectors, to secure the correct amount of glue in each hole,

- Control of dowel insert units,

- Touch screen in English ( also available in local language ),

- Possibility to add Ethernet connection in order to access the PLC online from our factory,

- Individual requests,

- And more.

Please contact us for specifications.

Working Procedure:

The working cycle of Dan-List BASP 2800 is the following:

- Place the work pieces in the magazine,

- Choose which drilling units should be activated and which should be deactivated,

- Start the machine,

- The work pieces are pushed into the machine and clamped pneumatically,

- In the first working station the work piece is drilled from the ends and from the top,

- Then the work piece is moved to second working station where the glue is injected in the end holes,

- In third working station, the dowels are inserted,

- In the fourth working station which is on the conveyor the work pieces are drilled from the side,

- The finished work piece is then taken out of the machine on the same conveyor where it was drilled, and then pushed onto runners which are placed next to the machine.

As the machine always works with items in each of the four working stations, the capacity is approximately 600 – 800 work pieces per hour, depending on cross drillings.

Set-up:

The set-up of the machine is easy and operator friendly.

The operator loosen two handles on the carriers for the boring units, slide the boring units to correct position and lock the handles again.

Each boring unit has a digital reader so correct position is easily found.

Individual requests for set up is also available, see other alternatives here.

Video Presentation:

For video presentation, please click here.

Dan-List BASP 2800 is CE approved.

| Recommended technical data for Dan-List Dowel Boring Machine Model BASP 2800 Individual sizes of work pieces by request |

|

| Capacity | 800/600 items per hour |

| Length of items, max. | 2,200 mm |

| Length of items, min. | 190 mm |

| Boring depth, max. | 100 mm |

| Consumption per boring unit | 1.1 kW @ 2,850 rpm |

| Sliding mechanism | air with oil-damping |

| Air pressure | 6 - 8 bar |

| Air consumption | 0.5 litre per working cycle |

| Machine length, including delivery system next to the machine |

5,400 mm |

| Machine width | 2,400 mm |

| Machine height | 1,800 mm |

| Machine weight | 2,600 kilos |